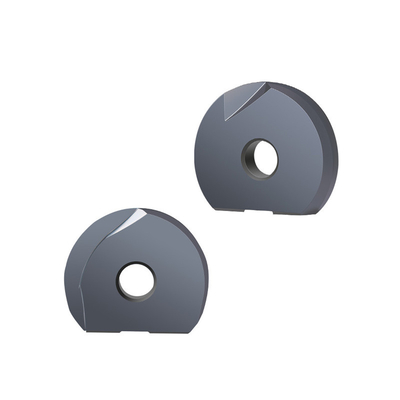

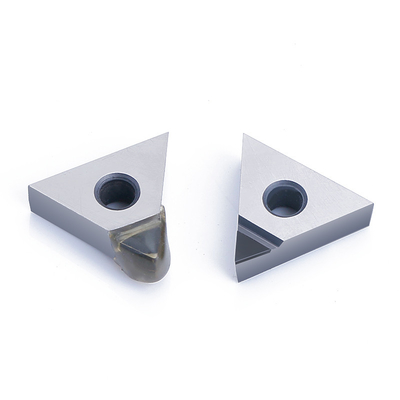

Composants de moules de poinçonnage personnalisés non standard Estampage à froid Matrices en carbure

Matrice d'estampage à froid en carbure non standard, Composants de moules de poinçonnage personnalisés

Domaine d'application

Les matrices d'estampage, également appelées matrices d'estampage à froid, sont largement utilisées dans les appareils ménagers, les communications électroniques, l'automobile et d'autres industries. Les principales classifications comprennent les matrices de découpe, les matrices de pliage, les matrices d'emboutissage et les matrices de formage.

Détails du produit - Matrice d'estampage à froid

- Rugosité de surface : RZ~~0.2um / F1.0mm/min

- Précision : ±0.001mm

- Personnalisation : Production entièrement personnalisée. Pas de stock standard disponible - seules les commandes non standard sont acceptées. Veuillez inclure des dessins CAO/dessins 3D avec votre demande.

Matériaux appropriés

| Matériau |

Propriétés des matériaux |

| Carbure |

Le carbure cémenté est un composite métallurgique des poudres composé de phases de matériaux durs (par exemple, le carbure de tungstène) et d'un matériau de liaison (par exemple, le cobalt). Caractérisé par une résistance élevée à l'usure et une stabilité thermique, il offre une durée de vie plusieurs fois supérieure à celle de l'acier à matrice, bien qu'avec un coût de matériau et une difficulté d'usinage plus élevés. |

| Céramique |

Les matériaux céramiques offrent une excellente résistance aux hautes températures (180°C à 1200°C) et aux produits chimiques, en particulier dans les solutions acides/alcalines. Les types courants comprennent l'alumine, la zircone, le carbure de silicium et les céramiques de nitrure de silicium. |

| HSS |

L'acier rapide offre une résistance supérieure à l'abrasion et une ténacité, idéal pour la production de petits lots ou les applications nécessitant une ténacité des matériaux. |

Technologie d'usinage impliquée

Les technologies de production comprennent : rectification cylindrique, rectification circulaire interne, rectification de profil optique, rectification plane, usinage de filetage, découpe au fil à vitesse moyenne/basse et usinage par décharge miroir.

Pourquoi nous choisir

- Technologie de pointe : Formation précise de formes et de structures complexes

- Traitement efficace : Cycles de production courts avec livraison rapide

- Qualité du produit : Précision élevée constante (±0.003mm)

- Confidentialité : Mesures de protection triples avec NDA optionnel

- Capacité de production : Lignes de production multiples avec des équipements de pointe

- Rentable : Prix compétitifs grâce à une conception et une sélection des matériaux optimisées

Kinyet est spécialisé dans la R&D des matériaux en tungstène, investissant continuellement dans les nouvelles technologies et les équipements haut de gamme pour fournir des moules de haute précision et de longue durée à des prix compétitifs. Désormais fusionné avec Drow, nous sommes en mesure de créer des produits encore plus excellents pour nos clients.

Critères de qualité

- Résistance à l'usure

- Précision

- Résistance à la corrosion

- Résistance aux chocs

- Ténacité

- Module d'élasticité/rigidité

- Résistance à la rupture transversale

FAQ

Q1 : Produisez-vous des composants spéciaux de moules de poinçonnage ou de matrices de poinçonnage ?

R : Oui, nous sommes spécialisés dans la fabrication de moules personnalisés, traduisant des concepts complexes de matrices de poinçonnage en réalité pour diverses applications et matériaux exigeants.

Q2 : Pouvez-vous envoyer des produits à notre transitaire en Chine ?

R : Oui, nous pouvons organiser l'expédition à votre transitaire désigné en Chine.

Q3 : La confidentialité est-elle possible pour notre coopération ?

R : Absolument. Toutes les informations de l'entreprise, les dessins et les détails de la commande restent confidentiels, avec une NDA optionnelle disponible.

Q4 : Quelles sont vos conditions de paiement ?

R : 30 % d'acompte par T/T, avec un solde de 70 % payé avant la livraison. Nous fournissons des photos du produit et de l'emballage avant le paiement final.

Q5 : Qui sommes-nous ?

R : Basés dans la province de Guangdong, en Chine, depuis 2010, nous servons les marchés mondiaux, notamment l'Europe occidentale (10 %), l'Amérique du Nord (20 %), l'Europe de l'Est (20 %), l'Asie du Sud-Est (40 %) et l'Afrique (10 %) avec une main-d'œuvre de 51 à 100 professionnels.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!