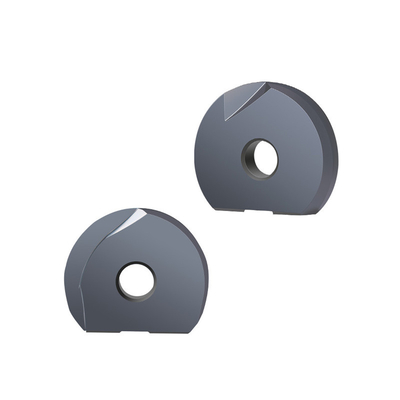

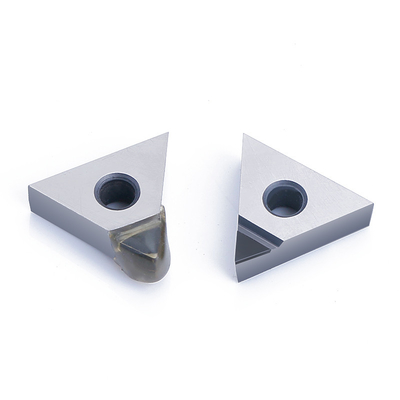

Composants de moules de poinçonnage HSS, poudre de carbure, matrice de métallurgie des poudres

Matrice de métallurgie des poudres en carbure à haute résistance à l'usure pour la mise en forme de pièces en alliage

Domaine d'application :Les moules de métallurgie des poudres sont largement utilisés dans toutes sortes de pièces en alliage formées. Leur haute précision et leur haute résistance à l'usure réduisent considérablement la perte de moules. Parmi eux, les moules de métallurgie des poudres non magnétiques sont utilisés dans la fabrication de produits de moulage de poudre magnétique, qui sont très compétitifs. Kinyet est en mesure de fournir une solution pour la fabrication de moules magnétiques en poudre avec notre série de qualité non magnétique.

Détails du produit - Matrices de forgeage personnalisées

- Rugosité de surface : RZ 0,2 um / F1,0 mm/min

- Précision : ±0,001 mm

- Personnalisation : Personnalisation absolue. Il n'y a pas de stock standard pour cette série de produits, et seules les commandes non standard sont acceptées. Veuillez joindre les dessins CAO/dessins 3D à votre demande.

- Matériau approprié : carbure de tungstène, céramique et HSS, etc., propriétés comme ci-dessous :

| Matériau |

Propriétés des matériaux |

| Carbure |

Le carbure cémenté est un composite de métallurgie des poudres composé d'une ou plusieurs phases de matériaux durs (par exemple, le carbure de tungstène) et d'un matériau de liaison (par exemple, le cobalt). C'est un matériau extrêmement dur, caractérisé par une haute résistance à l'usure et une stabilité thermique. Il est utilisé dans divers domaines qui nécessitent des outils ou des composants particulièrement résistants à l'usure. Par rapport à l'acier à matrice, il est plus difficile à usiner et a un coût de matériau plus élevé, mais sa durée de vie est souvent plusieurs fois supérieure à celle de l'acier à matrice. |

| Céramique |

Les matériaux céramiques ont une bonne résistance aux hautes températures et jouent un rôle décisif dans les applications à haute température dans la plage de température de fonctionnement continu de 180 °C à plus de 1200 °C. Par rapport aux matériaux métalliques, les céramiques d'oxyde sont considérées comme résistantes aux attaques chimiques, en particulier dans les solutions acides et alcalines. Les plus courantes sont l'alumine, la zircone, le carbure de silicium, les céramiques de nitrure de silicium. |

| HSS |

Acier rapide avec une résistance supérieure à l'abrasion et une ténacité pour une utilisation générale. Il est principalement utilisé dans la production en petits lots ou dans les domaines avec des exigences élevées en matière de ténacité des matériaux. |

Technologie d'usinage impliquée :

- Technologie de production impliquée : rectification cylindrique, rectification circulaire interne, rectification de profil optique, rectification plane, usinage de filetage, découpe de fil à vitesse moyenne, découpe de fil à basse vitesse, usinage par décharge miroir, etc.

Pourquoi nous choisir

- Technologie de pointe :Des formes complexes et diverses structures peuvent être rapidement formées et maintenues avec précision.

- Traitement efficace :Cycle de production court et livraison rapide, pour assurer le calendrier d'expédition selon la date de livraison.

- Qualité du produit :Qualité constante garantie. Haute précision, jusqu'à ±0,003 mm.

- Système de confidentialité :Triple mesures de confidentialité pour protéger. Si vous en avez besoin, nous pouvons signer un NDA (accord de non-divulgation), ce qui est plus sûr.

- Haut de gamme et entièrement équipé :Capacité de traitement exceptionnelle, multiples lignes de production, équipements de pointe, installations de soutien professionnelles.

- Rentable :Une conception et une sélection des matériaux raisonnables nous conduisent à un prix compétitif, ce qui pourrait vous aider à offrir un prix plus avantageux pour les produits de même niveau.

Kinyet se concentre en permanence sur la recherche et le développement de matériaux pertinents pour le tungstène. En introduisant constamment de nouvelles technologies et en augmentant les investissements dans les équipements de production haut de gamme, Kinyet est en mesure d'offrir des solutions de moules avec un rapport qualité-prix élevé, notamment une haute précision, une durée de vie des outils plus longue et une rentabilité, etc. Kinyet est désormais fusionné avec Drow. Grâce à cette combinaison puissante, nous pensons que nous créerons d'excellents produits pour les consommateurs à l'avenir !

Critères de qualité

- Résistance à l'usure

- Précision

- Résistance à la corrosion

- Résistance aux chocs

- Ténacité

- Module d'élasticité, Rigidité

- Résistance à la rupture transversale

FAQ

Q1 : Fabriquez-vous des moules de poinçonnage spéciaux ou des composants de matrices de poinçonnage ?

R : Oui, nous sommes spécialisés dans la fabrication de moules personnalisés et traduisons l'idée de matrices de poinçonnage les plus complexes en réalité, les composants de moules de poinçonnage fabriqués par nos soins sont conçus et personnalisés pour diverses applications exigeantes et une variété de matériaux !

Q2 : Acceptez-vous de faibles volumes pour les commandes d'échantillons ? Et quel est votre MOQ pour la personnalisation ?

R : Oui, c'est le cas. Pour les commandes d'échantillons, un MOQ d'une pièce est accepté. Veuillez joindre les dessins CAO/dessins 3D à votre demande et le délai d'exécution de l'échantillon est de 10 à 15 jours. Il peut être négocié pour d'autres exigences particulières.

Q3 : Si nous voulons coopérer avec vous, est-il possible d'obtenir la confidentialité ?

R : Bien sûr, toutes vos informations, y compris les informations sur l'entreprise, les dessins, les détails des bons de commande, seront conservées confidentielles, nous pouvons signer un NDA si vous le souhaitez (accord de non-divulgation).

Q4 : Quelles sont vos conditions de paiement ?

R : T/T 30 % comme acompte et 70 % du solde avant la livraison. Nous vous montrerons les photos des produits et des emballages avant de payer le solde.

Q5 : Quoi d'autre pouvez-vous nous acheter ?

R : Autres séries d'inserts, fraise en bout en carbure, foret en carbure, alésage en carbure, outils de coupe et moules de précision en carbure personnalisés.

Q6 : Pouvons-nous obtenir une remise si la quantité commandée est suffisamment importante ?

R : Oui. Si la quantité commandée est suffisamment importante, nous pouvons vous offrir notre meilleur prix et vous accorderons une remise.

Q7 : Pourriez-vous offrir un service OEM et ODM ?

R : C'est bon, nous avons plus de 10 ans d'expérience dans le service OEM. Notre équipe de R&D professionnelle se consacre à la conception de produits pour répondre aux diverses demandes des clients. Ils peuvent toujours vous offrir des conseils et des solutions professionnels !

Q8 : Qui sommes-nous ?

R : Nous sommes basés dans la province du Guangdong, en Chine, à partir de 2010, vendons en Europe occidentale (10,00 %), en Amérique du Nord (20,00 %), en Europe de l'Est (20,00 %), en Asie du Sud-Est (40,00 %), en Afrique (10,00 %). Il y a au total environ 51 à 100 personnes dans notre usine.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!